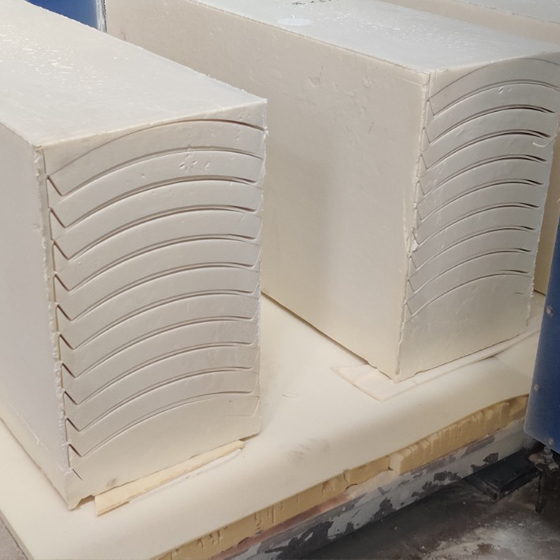

PIR foam pipe section is made from our PIR block, fabricated with wire cutting machine to different sizes of pipe in various segments and required insulation thickness, mainly used for thermal insulating purposes.

OPIPL CFC free rigid closed cell PIR foam is manufactured in similar way to standard Polyurethane which has all the characteristics and advantages of rigid Polyurethane foam but offers greatly increased resistance to burning and spread of flame and is able to withstand temperatures up to 140°C. When subjected to fire the outer surface of the foam forms a strong carbonaceous layer, which retards further flame spread and penetration. OPIPL CFC free rigid closed cell PIR foam has a low Thermal Conductivity of less than 0.023 W/m °C at 10 °C, gives excellent thermal properties and fire properties when tested in accordance with ASTM E84. With 95% closed cell content, low thermal conductivity values, high compressive strength, durability and dimensional stability. we can achieve optimal energy savings and provide long end satisfactory service life.

We have fully programmable Multi CNC Abrasive Wire cutting Machine for large PUF/PIR Insulated Pipe section manufacturing capacity, meeting national & International demand for various sizes of Pipe sections and Pipe Supports. These Pipe sections are designed by using most updated technology meeting the market needs. The complete range of Insulated PUF/PIR pipe sections are meticulously manufactured and examined on different provisions of quality parameters meeting International Standards.